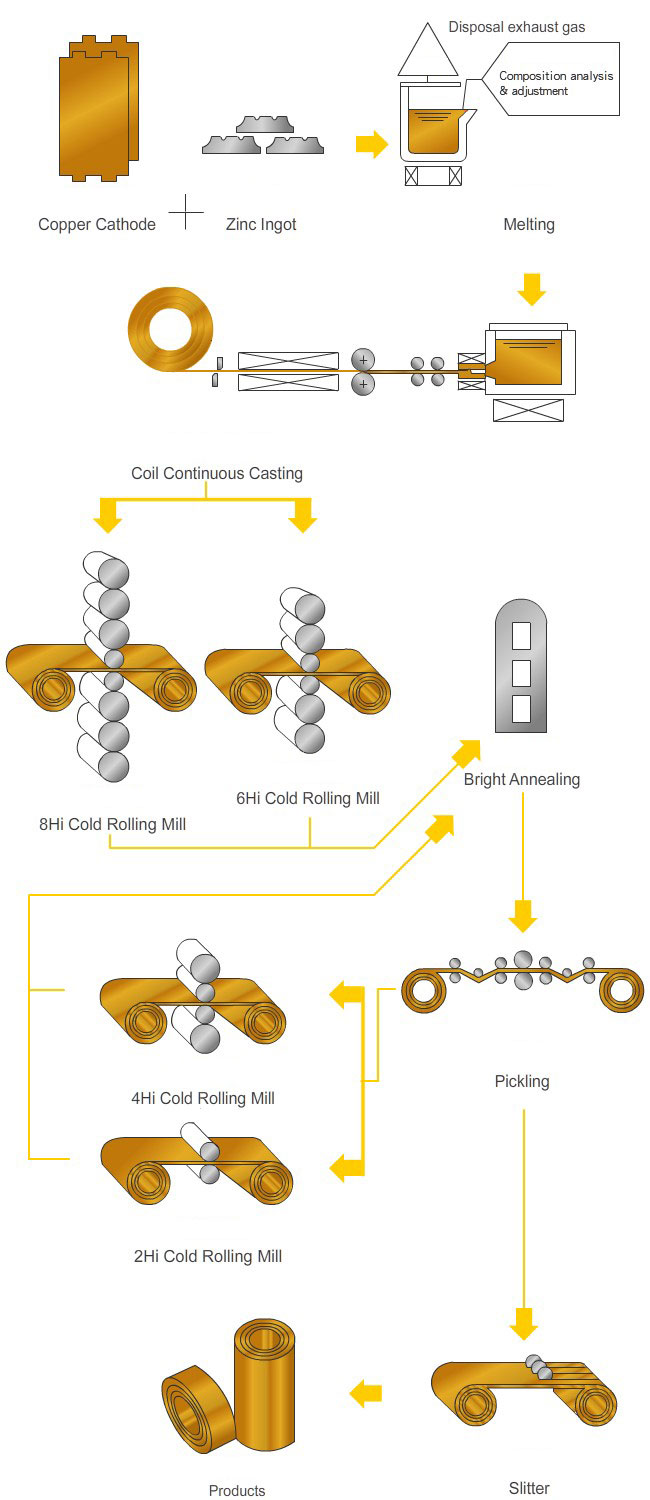

Equipment Introduction

- Smelter: smelts electrolytic copper plate and zinc ingots, then directs them into the continuous copper roll casting machine.

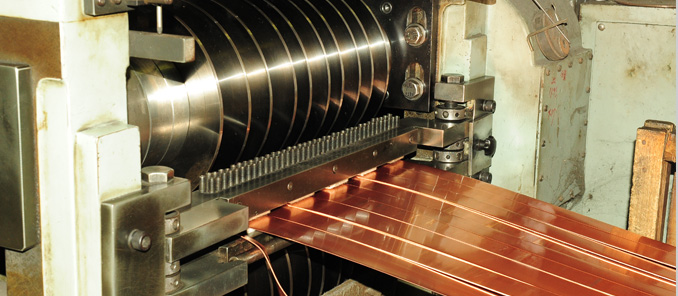

- Continuous copper casting and rolling machine: compresses raw material into the desired shape.

- 8-stage cold rolling sheet mill: reduces the thickness of cast copper plate to facilitate the bright annealing process.

- Bright annealing equipment: copper plate coming out of the 4-stage cold rolling sheet mill are primarily heated and annealed in a closed compartment; brightness is produced by slowly lowering the temperature to below 500 degrees in a closed compartment first, then cooling down further naturally in order to prevent decarburization.

- 6-stage cold rolling sheet mill: compresses copper plate to a specified thickness.

- 2-stage polished sheet mill: compresses copper plate to a specified thickness.

- Slitting machine: cuts and rolls copper plate longitudinally to fixed length and width to meet clients' requirements and facilitate packaging.

- Inspection: composition, hardness, tensile strength, extensibility, crystal grain size, thickness, and other properties are measured using specialized equipment to ensure that product quality meets customer requirements.